Strategies for Overcoming Electrical Component Failures in HVAC

Table Of Contents

Developing a Response Plan

A well-structured response plan is essential for mitigating the impacts of electrical component failures in HVAC systems. This plan should outline clear procedures that technicians and management can follow to identify the issue swiftly and implement corrective measures. Key elements of the plan include establishing communication protocols, detailing responsibilities for team members, and specifying the steps needed for diagnostics and restoration. Regular training sessions can ensure that all personnel are familiar with these procedures, enhancing the team's ability to respond efficiently under pressure.

Incorporating a detailed inventory of components and their specifications will help in diagnosing problems more effectively. Additionally, documenting past failures and responses can provide invaluable insights for future actions. This historical data assists in recognising patterns that may reveal recurring issues, enabling proactive measures to prevent similar occurrences. Regular reviews and updates of the response plan will keep it relevant, allowing the team to adapt to changes in technology and operational processes while ensuring ongoing reliability and efficiency of the HVAC system.

Steps to Take When a Failure Occurs

When an electrical component failure is identified, the first step is to ensure the safety of personnel. This includes shutting down the HVAC system and conducting an immediate risk assessment of the surrounding area. Isolating the faulty component may prevent further damage to the system and safeguard against potential electrical hazards. Proper training is essential, enabling team members to execute emergency procedures efficiently.

Once safety measures are in place, troubleshooting can begin. Documenting the failure will provide insights into its cause and may help identify patterns that signal repetitive issues. Testing other components in the system can clarify whether the failure is isolated or indicative of a larger problem. Collecting data on the incident will assist future planning and improve the overall response to similar situations.

Investing in Backup Systems

Incorporating backup systems can significantly reduce the risks associated with electrical component failures in HVAC systems. These alternatives serve as a safety net, ensuring that operations continue smoothly even when primary components fail. The initial investment may be higher, but the long-term savings in terms of downtime and repair costs can outweigh these expenses. Additionally, having backup systems enhances overall reliability and instills confidence in facility management.

Redundant systems are designed to operate seamlessly alongside primary components, which allows for quick switchover when needed. This reduces the chances of total system failure. Selecting high-quality backup systems also ensures compatibility with existing infrastructure, simplifying installation and integration processes. Ultimately, investing in robust backup options can lead to improved performance and longevity of HVAC systems.

Advantages of Redundant Systems

Incorporating redundant systems can significantly bolster the reliability of HVAC operations. These systems provide an immediate alternative should a primary component fail. This not only minimises downtime but also ensures that critical temperature control remains uninterrupted. Such an approach is especially vital in environments where temperature regulation is essential for operational integrity or product safety.

Moreover, redundant systems enhance overall system design by allowing for maintenance and upgrades without service interruption. Technicians can work on one system while another continues to operate, streamlining scheduled inspections and repairs. This proactive approach can lead to a longer lifespan for HVAC equipment, reducing the frequency of costly replacements. Overall, investing in redundancy is a strategic move that provides stability and peace of mind in HVAC management.

Enhancing System Design

Incorporating resilient components into the HVAC system design can significantly reduce the likelihood of electrical failures. By selecting high-quality materials known for their durability and resistance to wear, system reliability improves. For instance, using components rated for higher voltage or temperature thresholds can help mitigate the impact of environmental stressors. Additionally, integration of flexible circuit designs allows for easier maintenance and replacements, reducing downtime and operational disruptions.

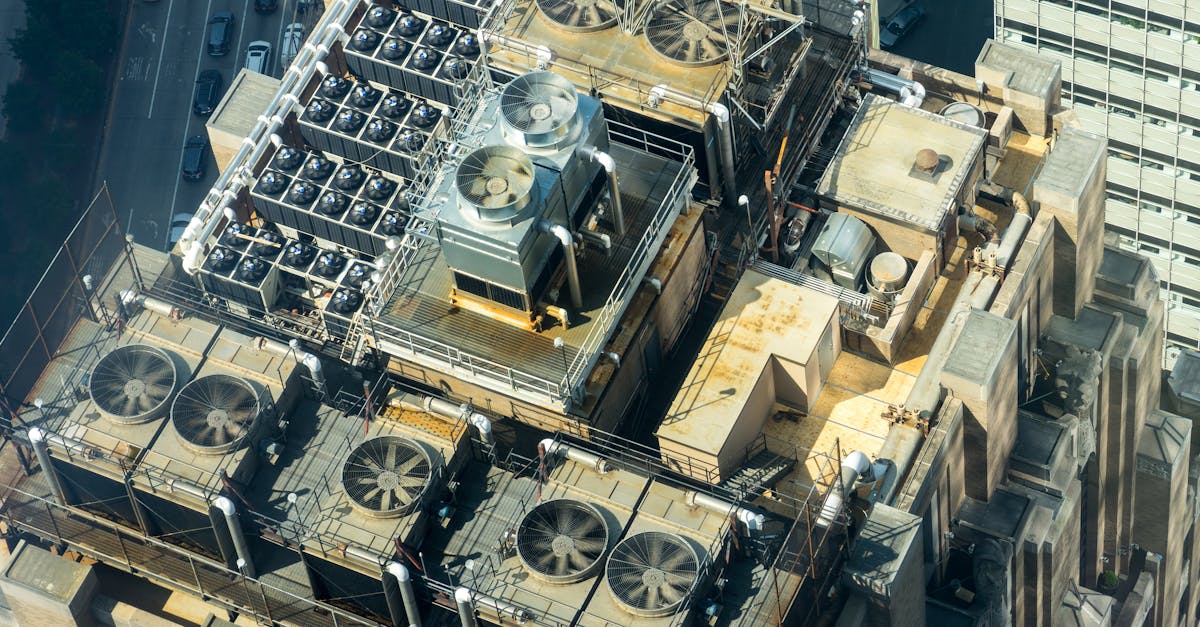

Another crucial aspect is ensuring proper ventilation and cooling for electrical components. Efficient airflow around sensitive parts can prevent overheating and prolong their lifespan. Strategic placement of components within the system enhances accessibility, making it simpler to conduct routine inspections and maintenance. These thoughtful design choices create a more robust HVAC system that can withstand unforeseen challenges, ultimately leading to enhanced efficiency and reduced operational costs.

Integrating Resilient Component Choices

Choosing components with a proven track record for durability can significantly reduce the risk of failures in HVAC systems. Seek out materials that are resistant to environmental factors, such as humidity and temperature fluctuations. Selecting suppliers known for their high-quality manufacturing processes ensures that the components can withstand the operational demands placed on them. Research also highlights the importance of compatibility; components should work harmoniously together to avoid undue stress on any single part.

Adopting advanced technologies can enhance component resilience even further. For instance, employing smart sensors can provide ongoing monitoring of system performance, allowing for early detection of potential problems. This proactive approach enables maintenance teams to address issues before they lead to downtime. Furthermore, utilising energy-efficient components not only extends system life but also contributes to lower operational costs, making the entire HVAC system more economical in the long run.

FAQS

What should be included in a response plan for electrical component failures in HVAC systems?

A response plan should include identification of critical components, procedures for troubleshooting, contact information for service providers, and a clear communication strategy for informing stakeholders.

What are the first steps to take when an electrical failure occurs in an HVAC system?

The initial steps include turning off the system to prevent further damage, assessing the situation to identify the issue, and consulting the response plan to determine the next actions to take.

What are the benefits of investing in backup systems for HVAC?

Backup systems provide redundancy, ensuring that HVAC operations can continue during a failure, reduce downtime, and enhance overall system reliability, which ultimately leads to cost savings in the long run.

How do redundant systems work in HVAC applications?

Redundant systems operate by having multiple components that can perform the same function, allowing one to take over if another fails, which ensures uninterrupted operation and enhances system resilience.

What resilient component choices should be integrated into HVAC system design?

Resilient component choices include high-quality materials, components with a proven track record of reliability, and designs that allow for easy maintenance or replacement, all aimed at minimising the risk of failures.

Related Links

Managing and Eliminating Indoor Air Quality Issues in HVACResolving Air Flow Issues in Large Scale HVAC Installations

Effective Methods for Preventing Condensate Drain Blockages

Solutions for Uneven Temperature Distribution in Large Spaces

Troubleshooting Inefficient Cooling Performance in HVAC Systems

Addressing Short Cycling Problems in Commercial HVAC Solutions